Rubber Type Expansion Joints

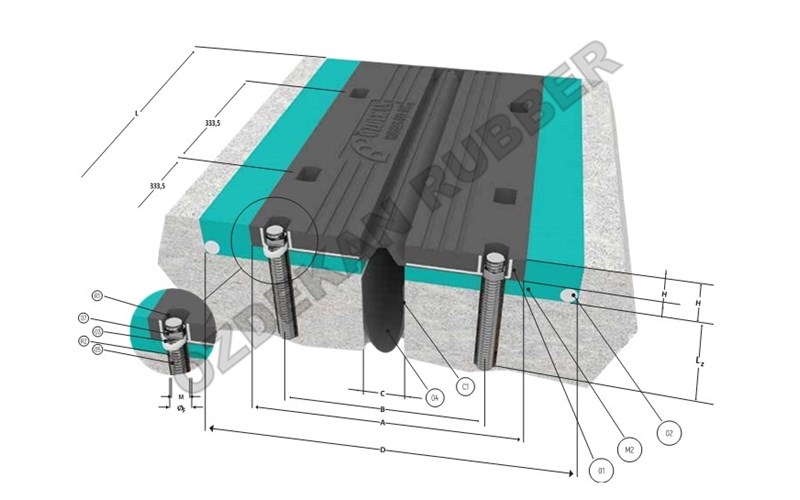

The Ozdekan EX are waterproof expansion joints that allow absorption of the deck movements. These joints are manufactured with rubber elements and restrained to the structure with proper anchor bolts.

The reinforcing metal profiles made of steel are completely inserted and vulcanized to the rubber. This process is a total guarantee against corrosion and allows a longer life to the product.

The rubber compound, too, has been intentionally formulated to resist the oil, grease, petrol, salt and sand, without besides, suffering premature ageing phenomena due to sun rays, salt and snow.

All the joints follow the deformations and movements of the structure (the movement can exist with every skew angle from 0° to 90°) by shear deformation of the rubber elements.

Anchor bolts, made of steel and protected with anticorrosion treatments, absorb the elastic reactions and all the other kind of mechanical solicitations.

The joints are also able to compensate height difference or vertical movements. This characteristic is very important in all the cases where load and movement conditions can cause relative vertical movements. The joint series is manufactured by Ozdekan since 2006.

Main advantages:

Simple and linear design with few elements

Low height of the profile

Total impermeable

Easy assembling eitheron concrete structure

Suitable for the replacement of existing joint

Easy and quick to be replaced

Good resistance to vehicles sliding

Vertical movements absorption

The joints are supplied in variable length elements depending to the joint type. A joint line consists in fact of many units joined together with a groove-and-tongue junction welded with special glue. The joint fixing is obtained by chemical anchors; the nuts are locked using a dynamometric key so that permanent compression strength is given to the joint. Stainless steel anchors may be provided on request. In that way the horizontal forces, due to breaking of vehicles and to the reaction that rubber opposes to the joint deformations (shrinkage, creep, thermal variations etc.), are transmitted by friction between the rubber and the concrete. The joints can be assembled on a metallic infrastructure. The joints of bigger movements with four upper grooves are manufactured in order to prevent the lifting of the elements during the contraction. These devices guarantee the adhesion of the elements to the structure and the noiseless of the traffic.